|

Spur Gears, Bevel Gears, Worms.

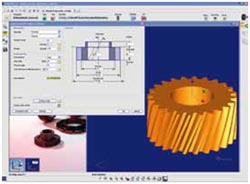

GEAR PRO – CAD-based gear wheel software |

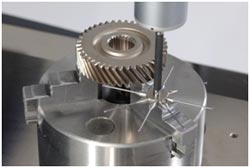

Used together with CALYPSO, the GEAR PRO line enables you to inspect spur gears, bevel gears and worms. GEAR PRO generates a CAD model of the gearing from the geometry definition. The graphic display allow separators to quickly and visually check their input values. A standard measurement can be performed immediately based on the definition of the geometry. |

|

| |

All GEAR PRO programs feature the same easy-to-use interface. Gear measurements can be started either automatically from a CALYPSO measurement plan or manually in the corresponding GEAR PRO program.

The analytical 3D gear tooth model and the graphic-supported input windows make measuring with GEAR PRO highly effective. The software enables measurements with or without a rotary table. Several measuring runs can be defined per measurement plan and features can be turned on and off. An optional qs-STAT interface is available for statistical evaluation. |

|

| |

| GEAR PRO involute was specially developed to Measure spur gears. |

• |

Straight or slanted-tooth spur gears |

• |

Conically corrected gears |

• |

Splines |

|

| GEAR PRO bevel measures and evaluates bevel gears. Nominal values can either be imported via the CAD interface (Gleason, Klinglenberg, Daimler-ZAFE, CCDS) or generated by digitizing a master gear. |

| GEAR PRO worm is used to measure worms. GEAR PRO worm takes into account the different geometries from ZA, ZI, ZK and ZN worms |

| |

| GEAR PRO Involute- Product specification |

| Supported Gear: |

| 1. |

Cylindrical Gear: |

| |

• |

With involute profile |

| |

• |

External & Internal Gear |

| |

• |

Spur & Helical Gear |

| |

• |

Splines |

| 2. |

No Of teeth : |

| |

• |

1-1000 |

| 3. |

Module : |

| |

• |

> 0.5 (depends on stylus tip diameter) |

| 4. |

Helix Angle : |

| |

• |

< 89.9° |

|

|

|

| Measurement Run : |

• |

Profile |

• |

Lead |

• |

Pitch /Runout (single Flank/Double Flank , Self-centring) |

• |

Tip & Root Circle Diameter |

| Features : |

• |

Import & Export from nominal data from via GDE-interface |

• |

Different geometry data on left & right flank |

• |

Missing teeth |

• |

Interrupted lead |

• |

Intersection Measurement |

• |

Element Selection left and or right flank |

• |

Different tolerance on left and right flank |

• |

Asymmetrical Tolerance |

• |

Tolerance for mean value |

• |

Scanning Nominal path or scanning actual path (Measurement on Big deviation possible) |

• |

Calculation of deviation in axil Transversal Or Nominal Plane |

• |

Topography presentation. |

• |

Tooth gap measurement |

• |

Automatic stylus system selection at measurement |

• |

Raster line /horizontal marker line on print out |

|

| Evaluation : |

| Standards : |

• |

DIN 5480 |

• |

ISO 1328 |

• |

AGMA 2000-A88 |

• |

ANSI B92.1 |

• |

JIS B1702 |

• |

Free definition of tolerance values |

• |

Customer specific standards (Scania, Volvo, ZF, Renault) |

| Profile : |

| • |

Profile Total Deviation Fα |

| • |

Profile Form Deviation ffα |

| • |

Profile Slope Deviation fHα |

| • |

Profile Crowning ch |

| • |

Profile Tip Relief ca |

| • |

Profile Root Relief cf |

| • |

K Diagrams |

| Lead |

| • |

Lead Total Deviation Fβ |

| • |

Lead Form Deviation ffβ |

| • |

Lead Slope Deviation fHβ |

| • |

Lead Crowning cb |

| • |

Lead End relief Top co |

| • |

Lead End relief Bottom cu |

| • |

K Diagrams |

| Pitch/Runout |

| • |

Accumulated Pitch Deviation Fp |

| • |

Pitch Span Deviation Fpz/8 |

| • |

SinglePitchDeviation fp |

| • |

SpacingDeviation fu |

| • |

Runout Fr |

| • |

ToothThicknessVariation Rs |

| • |

ToothThickness Ss |

| • |

GapWidth Es |

| • |

Dimensionover1-ball MrK |

| • |

Dimension over 2-balls MdK |

| • |

Dimension over 2-pins MdR |

| • |

Spanwidth over k teeth Wk |

| • |

Lead Height |

| • |

Output of eccentricity corrected values possible |

| Tip circle diameter : da |

| Root circle diameter : df |

|

| Supported Gear : |

| Bevel gears : |

| Pinion |

| Worm pinion (high reduction pinion) |

| Ring gear |

| Dies |

| Spur and spiral gearing |

| Number of teeth |

| 1 – 1000 |

| Module |

| > 0,5 mm (depends on stylus tip diameter) |

| Spiral angle |

| < 80° |

|

|

|

| Measurement runs: |

| Measurement with rotary table Main axis Z-axis (vertical direction) |

| Measurement without rotary table (NSP for ring gears and spur pinions) |

| Feed-In direction Z-axis (ring gear) |

| Feed-In direction X-axis (pinion) |

| Topography |

| Pitch/Runout (single flank measurement) |

| Tip cone |

| Root cone |

| Flank form nominal points |

| Nominal data import via various interfaces |

| Nominal data generation using a master gear (creation up to 3 sub grids possible) |

| Nominal data generation via CAD-Model (SAT, STEP, IGES) |

| Interfaces (optional): |

| Name of interface |

Actual data export for correction data calculation |

Standard (ASCII/Bevel Unix) |

- |

RAM-300-Data (CMS) |

- |

Gleason (GAGE4Win) |

Manual/Automatic |

Klinglenberg (KIMOS) |

Manual/Automatic |

Oerlikon (CDS) |

Manual |

DaimlerChrysler (ZAFE) |

Manual/Automatic |

|

|