| |

|

|

| CNC Gear Testers |

|

|

|

| |

|

|

|

|

|

| |

|

|

|

|

| |

|

|

| Gear Roll Testers |

|

|

|

| |

| |

| |

| |

We are leaders in Gear Metrology & Industrial Metrology.

We are in the field of Gear Measuring Machines and 100% Automated Inspection and Sorting Machines for Auto Parts. We do Servicing, Rebuilding & Computer retrofitting of various makes & models of Gear Testers & many Metrology Instruments such as Roundness Testers, Contour measuring Machines etc. Based on your requirements we built the machine for 100% Automated Precision Inspection and Sorting for Auto Parts. |

| |

| Gear Measuring Machines : |

| |

| |

| Rebuilt Machines & PC Retrofits for Gear Measurement |

| We also offer Rebuilt & PC Retrofit Gear Testers of various makes and models such Maag pH60 / SP60 / PH100, Hofler EFRS 401 / 631, ZP260, Klingelnberg PFS600 / PFSU-640 Goulder Mikron IL 600, David Brown18T, Osaka Seimitsu, FrencoSH450, etc. |

| |

|

• Installation and commissioning |

• Repairs and diagnosis of faults at sites

|

• Acceptance tests with traceable masters

|

| • Preventive Maintenance |

| • Service Training |

| • Application Training |

• Stock and sale of spare parts

|

| • Free Telephone Support |

| • Up gradations |

| • Consultations on site preparation |

|

| |

| |

| 100% High Speed Automatic Inspection, Sorting Machine for Auto parts |

|

| |

| Don’t ship another bad part - Prime Tech can offer Zero Reject 100% Inspection Quality |

| |

|

| |

At Prime Technologies, inspection goes way beyond simple machine vision. With a broad spectrum of tools in our arsenal, we can offer a variety of inspection equipment from World leaders in this field. From robot-integrated machine vision for high speed sorting and packaging, to ultra-high resolution measurement systems to verify dimensions and inspection of surface cracks on precision machined components, Prime Technologies can offer inspection machines to complete the most demanding inspections.

Some Precision parts for which we provide Inspection, Measuring & Sorting Machines are Bearings, Fasteners, Gaskets, Disc Springs, Brake Disc, Spool, Rotor, Cam Ring, Camshaft, Crankshaft, Camring, Casing and any mass produced precision part

|

| |

| |

Training Division

As it is

Industrial Gauges & clamping devices:

As it is

|

| |

| |

All Metrology Instruments / Machines are important in any Metrology lab. Therefore it is very important to keep the instrument / machine in excellent working condition capable of providing reliable measurement results.

To achieve this task it is important to Service / Calibrate / Recondition/ Geometrically align the Measuring instrument / machine from time to time

Advantages

1. Life will be increased

2. No costly rejections and possible loss of business

3. No unwanted breakdowns which will affect productions and deliver schedules

4. Important requirement according to ISO / QS audit

5. No expensive purchase of New Machines

In addition to repair or service of above equipment our engineer will inspect your Metrology lab & equipment and make suitable suggestions.

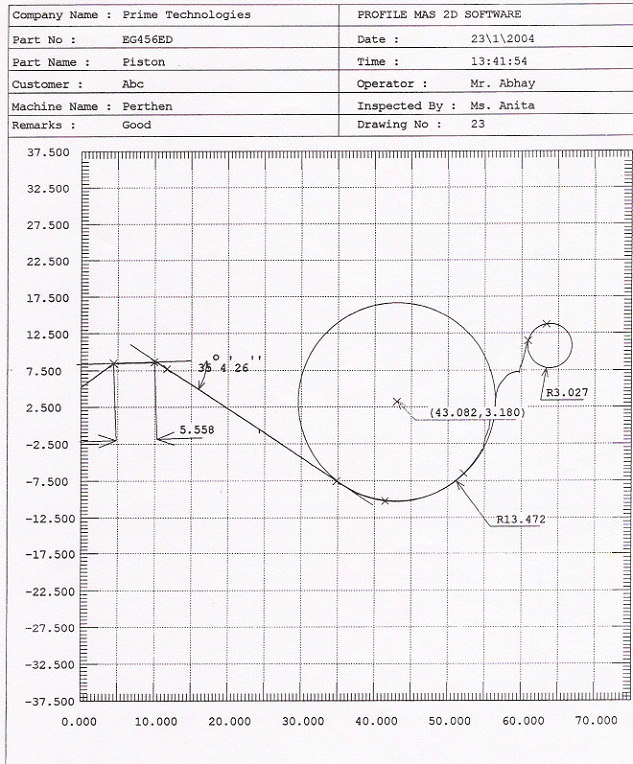

Pc Retrofit for contour Measuring Machine

• Contour Measuring Machine Consist of drive unit with recorder

• No spare are available and are very costly

• Manual evaluation of contour profile

In view of the above and many other disadvantages of recorder based system. We offer PC based system for contour Measurements and Analysis CONTOUR MASTM. This system can be retrofitted to any make viz. Perthen Rank Taylor Hobson, Hommel, Mitutoyo etc. and compatible to either LVDT type or Linear scale type if sensor.

Contour Data Analysis

• Provides Dimensional analysis of Geometric features such as radius, angle, length & heights

• Tolerances for individual feature

• Comparison of measured profile with a master profile

• The true functional of elements can be examined by means of geometrics references such as least Squares Arc. Least Squares Line.

• Apart from Contour data analysis it can also evaluate from errors

• Stylus radius compensation

• Results in Cartesian co-ordinate system or polar co-ordinate system

Advantage

• Comprehensive upgrade utilising state –art-computer data processing technology

• Enhances the life of contour Measuring Equipment.

• Menu Driven and function key operation.

• Fast & Accurate evaluation of parameter

• Very low cost.

• No-problem of service and spares

• No special expensive graph recording paper is required

|