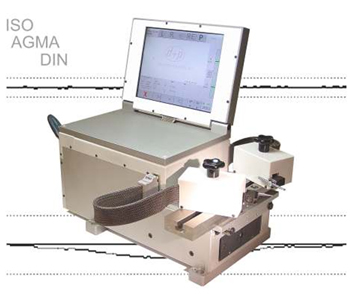

| PORTABLE CNC PITCH TESTER ES 4100 |

|

| The measuring instrument |

|

ES4100 closed

The new portable pitch measuring instru ment ES 4100 of f ers an extremely exact method of measureme nt based on the principle of chord measure ment (co mparator method).

A high degree of operational convenience is possible by

the built in processing of the measured data and the t ilt a nd sw ivel display touch-screen. |

|

ES4100 metal casing

The qua lity level of the gear teeth is easily deter mined by the evaluation sof tw are to ISO, DIN or AGMA standards.

The result of the measure ment is displayed immed iate ly by the apparatus itself, and stored.

For docu mentation the result can also be printed out via the w ireless printer connection. |

|

Swiv elling monitor

Existin g pitch measuring instrume nt ES401 f rom the MAAG

company can also be upda ted on request. |

| |

| Operation |

|

Operating principle

The portab le pitch me asuring instru ment can be used in many production locations.

The on ly prerequisite f or its use is a slow ly rotating w ork-table or an appropriate arrange ment be tw een centres, w here the

work piece to be me asured can be accommodated.

The instrument is theref ore employed d irectly on the machine tool or as a supple mentary device on measuring centres. |

|

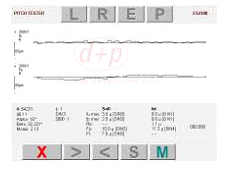

Display of measuring results directly on the apparatus

The operator is gu ided through the setting u p and the measure ment; w here the tuition t ime is minima l, and measure ments are perf ormed auto matically.

Measure ments are stored auto mat ically in th e instru ment and can be recalled via the part nu mbers identif ications. |

|

Wireless printer connection

The records are printed out via w ireless printer or via Me mory stick.

The measure ments can be stored and printe d out on an

external PC in the

form of an Adobe Acrobat PDF file. |

|

Transportation box

For safe handling is a transportation box and hood provided

|

Options :

Wireless printer Measuring device for internal gears |

| Transportation bar |

External display |

|

|

| Pick-up arm specifications : |

| Ope rating range : |

| • |

Maximu m measuring depth |

125 mm |

| • |

Span with probes |

40 mm |

| • |

Minimum diameter capacity |

250 mm |

| Dimensions : |

230 x 230 x 170 mm |

| Weight: |

5 kg |

| Accessories : |

Transportation case Necessary screws and tools |

|

TECHNICAL DATA :

Workpiece Dia meter Min/ Max: |

METRIC

10 mm |

INCH

0.4" unlimited |

Min./ max. Modu le / DP: |

1.0 - 40 Mod. |

25.4 - 0.63 D. P. |

Max. Nu mber of Teeth: |

999 |

|

Circu mf erential speed

of w orkpiece, variable 1 - 12 mm/ sec: |

04" - .472"/ sec. |

|

Left / Right hand measurement changeover: |

manual |

|

Radial Slide adjustment (range) : |

70 mm |

2.755" |

Probe span ( max): |

250 mm |

9.84" |

Magnification for diagrams |

|

|

Selectable: 100, 250, 500, 1000, 2000 |

Net weight (approx.): |

28 kg. |

62 lbs. |

Dimensions of ES4100 unit: |

550 x 350 x 250 |

21.6" x 13.8" x 10" |

Per missible measuring uncertainty: 2s range |

|

|

f p: ± 0.1 µ m / Guaranteed ± 0.2 µ m |

|

|

| Fp: ± 1.0 µ m / Guaranteed ± 1.5 µ m |

|

|

| Fr: ± 0.2 µ m / Guaranteed ± 0.4 µ m |

|

|

| Pow er Require ments: |

110 / 220 Volts |

50/60 Hz. ± 10 % |

| Machin e Color: |

Light Grey |

|

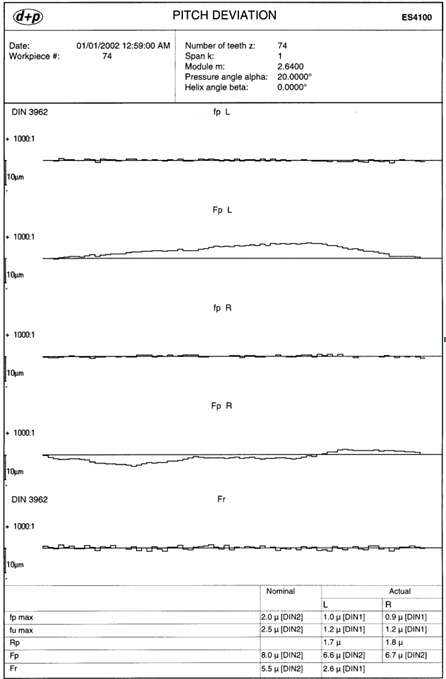

| The evaluation comprises of the following parameters and evaluated per: |

| |

ISO 1328 , AGMA 2000, 2015 an d DIN 3962 . |

Numerica l printout of ind ividual tooth values f or each tooth is also possible in t ext and Exel file. |

|

The Result

|

| |

|