All modules are designed in a similar concept.

The base frame is identical for all, the principal

mechanics also. Electrics and SPC are mounted

on plates that may be fixed on any side of the

module or in the control cabinet. Thus, even the

most simple module with manual loading may

be extended to an entirely production integrated

one. You then can add a smoothing module etc.

Only very few parts are depending on the part to

be tested, the overall design is quite simple and

thus easy to maintain.

|

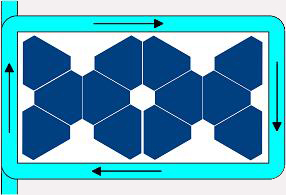

Modularity concept

Why pay for anything you do not need?

You like to be able to increase unctionality,

variety and through-put at any time?

|