|

|

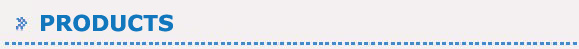

Precision Gear (Topological) Grinding

Based on Maag Machine from Donner + Pfister AG |

|

We are pleased and proud to inform you that Prime Technologies has

partnered with Donner + Pfister as Business partner for Gear Grinding

Based on MAAG Machine.

Under the partnership Prime Technologies will market & Support D+P products in India.

Up gradation / Supply of MAAG gear grinding machines based on the 0° grinding method by

incorporating topological control systems - with levels up to CNC.

A data-compatible substitute for MAAG-topology ES 422 is also available.

Suitable MAAG gear grinding machines are; HSS 30, SD-32X, SD-36X, HSP-80, HSS90, Others on

request

If necessary, the machine can undergo a mechanical overhauling.

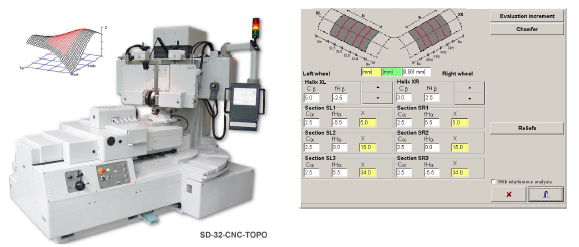

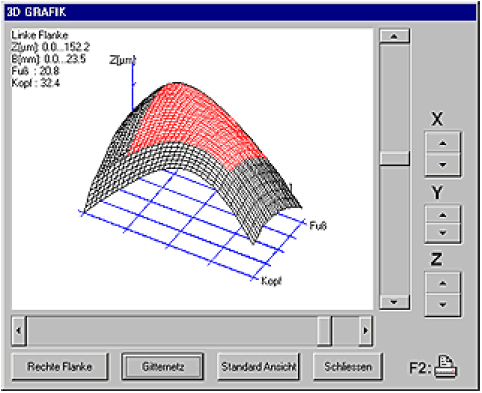

Reproducible topological corrections on tooth flanks, with short set-up times, highly precise, and at

economical cost. Different topological corrections can be ground on the left and the right flank

simultaneously

|

| |

| Highlights |

• Uniformly High Accuracy |

• Same grinding wheels for all pitches |

|

• Simultaneous grinding of two flanks

|

|

• Rapid changeover, Large machine capacity |

|

• Dry grinding process, Fully automatic grinding cycle |

|

• Easy programming of the topological flank

modifications

|

|

• Standardized input data according to DIN 3960. Simple

process for establishing standard modifications.

The

modifications are defined by way of cJ3, fHJ3,and co, fHa.

|

|

• Graphical in 2D |

|

• Standard for interchange (ASCII) Interface to load

topological control-and setting data |

|

A proved system since 17 years with a high availability and

designed for a long lifetime with the newest components to

grant availability of spare parts. |

| |

|

|

|

|

|

|

|

|